Heartwarming Tips About What Is A BOM In Logistics

Logistics Management PDF Bomb Disposal

Unlocking Logistics

1. The Secret Recipe of Supply Chains

Ever wondered how that cool new gadget you ordered online magically appears at your doorstep? It's not just fairy dust (though a little wouldn't hurt!). It involves a complex dance of parts, processes, and people, all orchestrated with the help of some very important documents. One of the most crucial of these documents, especially when dealing with physical products, is the Bill of Materials, often shortened to BOM. In logistics, the BOM is a foundational element, acting as the linchpin for efficient operation.

Think of a BOM like a detailed recipe for your favorite dish. It lists every ingredient, the exact quantity needed, and even instructions on how to combine them. In the context of logistics, a BOM breaks down a product into its individual components — raw materials, sub-assemblies, parts — and specifies the quantity of each required to manufacture the final product. It's the definitive list, the go-to guide, and the single source of truth for everything that goes into making something real. Without a clear BOM, chaos reigns supreme, leading to delays, errors, and a whole lot of head-scratching.

The BOM in logistics, importantly a noun, doesn't just list ingredients. It also specifies the type of material, like the kind of steel, the type of packaging, or even the specific vendor from which a particular item should be sourced. This level of detail is crucial for ensuring consistency, quality control, and regulatory compliance. After all, you wouldn't want your gourmet burger to suddenly arrive with questionable mystery meat, right? That's why the BOM is a vital instrument.

So, why all the fuss? Well, imagine trying to build a house without a blueprint. You might end up with walls in the wrong places, doors that don't open, and a roof that leaks. A BOM prevents similar disasters in manufacturing and supply chain management. It provides clarity, facilitates communication, and ensures that everyone is on the same page, from the procurement team ordering raw materials to the assembly line workers putting everything together. It really is the logistical backbone of many operations.

The BOM's Role in the Grand Logistics Symphony

2. Conducting the Orchestration of Goods

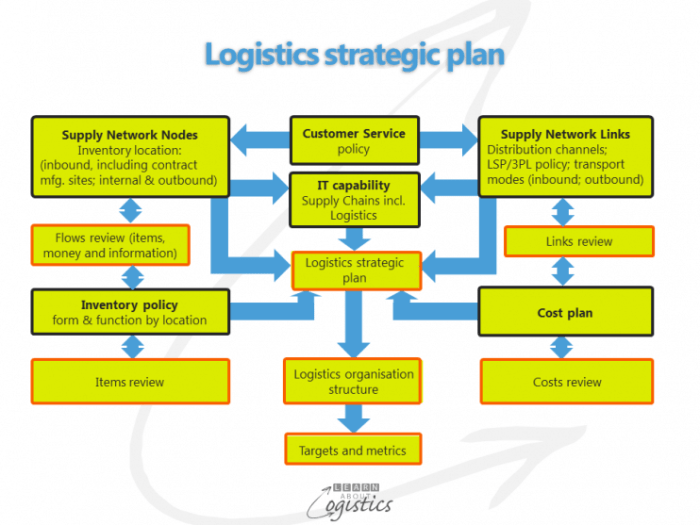

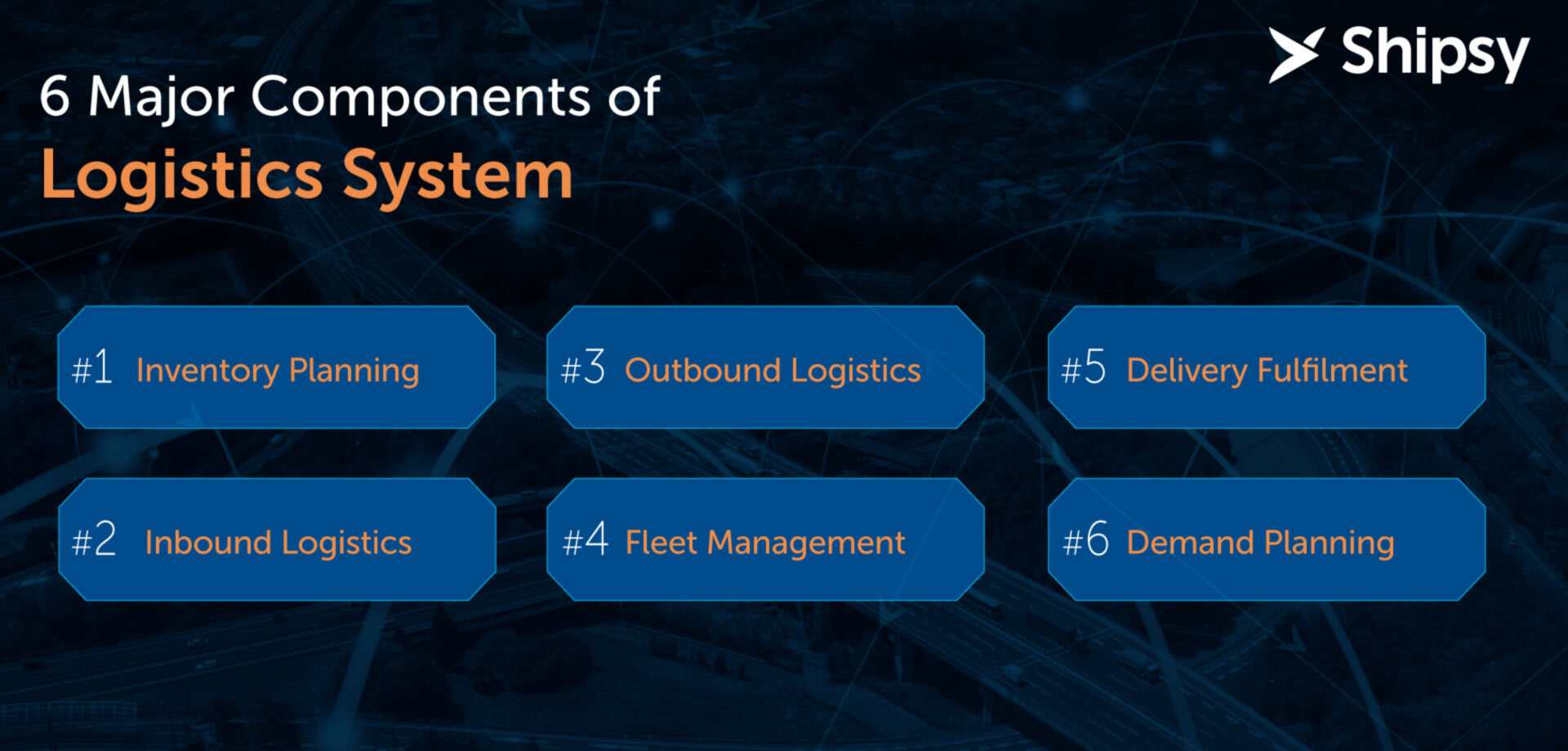

The BOM doesn't exist in a vacuum. It's a crucial player in a much larger logistical ecosystem. It directly impacts several key areas, from inventory management and production planning to cost control and procurement. Think of it as the conductor's score in an orchestra, guiding each section to play its part in harmony.

For instance, accurate BOMs are essential for effective inventory management. By knowing exactly what components are needed to produce a certain number of units, companies can optimize their stock levels, avoiding both costly stockouts and wasteful overstocking. This translates to lower storage costs, reduced waste, and improved cash flow. It's a win-win situation for everyone involved, from the company's bottom line to the environment.

Production planning also heavily relies on the information provided in the BOM. With a clear understanding of the components required and their lead times, manufacturers can schedule production runs more efficiently, minimize bottlenecks, and meet customer demand on time. No more angry customers waiting impatiently for their orders! A well-defined BOM ensures a smooth and predictable production process.

Beyond operational efficiency, BOMs also play a critical role in cost control. By tracking the cost of each component, companies can identify opportunities to reduce expenses, negotiate better prices with suppliers, and optimize their overall production costs. Furthermore, the BOM facilitates accurate cost accounting, enabling businesses to understand the true cost of their products and make informed pricing decisions. It gives managers the data needed to make strategic choices.

What Are The Different Types Of BOMs? YouTube

Types of BOMs

3. Navigating the BOM Landscape

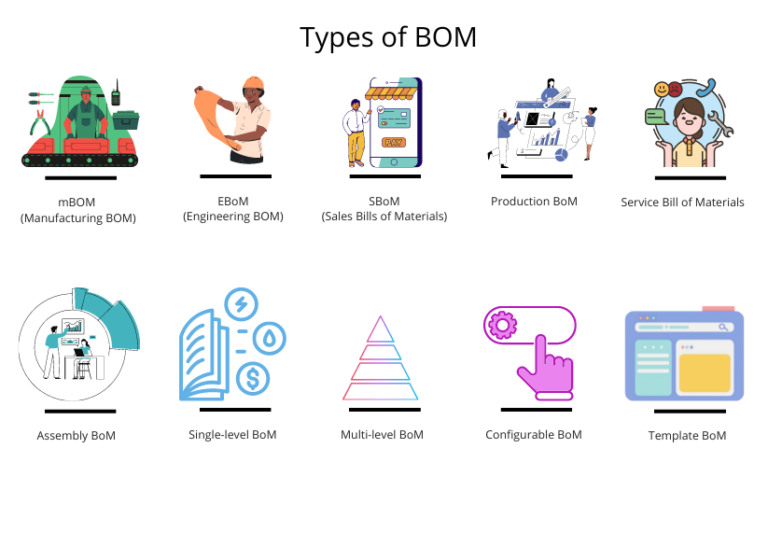

Just like there's more than one type of pizza (thank goodness!), there are also different types of BOMs. The best one for you depends on the complexity of your product, your manufacturing processes, and your specific business needs. Let's explore some of the most common types.

The most basic type is the "single-level BOM," which simply lists all the components that make up a product. It's a straightforward approach, ideal for simple products with relatively few components. However, for more complex products with multiple sub-assemblies, a single-level BOM can become unwieldy and difficult to manage. Imagine trying to bake a multi-layered cake with a recipe that only lists the ingredients — you'd be lost in a sugary mess!

A "multi-level BOM," also known as an "indented BOM," provides a hierarchical breakdown of the product, showing the relationship between the finished product, its sub-assemblies, and individual components. This type of BOM is much better suited for complex products, as it provides a clear and organized structure that makes it easier to understand the product's architecture. Think of it like a family tree, showing the lineage of each component and its place in the overall product structure. The Multi-Level BOM provides a superior organizational tool.

Another type is the "configurable BOM," which is used for products that can be customized or configured to meet specific customer requirements. This type of BOM allows for variations in the product design, enabling manufacturers to offer a wide range of options without having to create a separate BOM for each variation. Think of it like a build-your-own-burger menu, where customers can choose their toppings, sauces, and buns to create their perfect culinary creation. It offers both variety and efficiency.

Finally, there's the "engineering BOM" (EBOM), created during the product design phase, and the "manufacturing BOM" (MBOM), used in the actual production process. The EBOM focuses on the functional aspects of the product, while the MBOM focuses on the manufacturing process and the materials required. These two types of BOMs often work together to ensure that the product is both well-designed and easy to manufacture.

BOM Software

4. Embracing Technology for BOM Management

Managing BOMs manually, especially for complex products, can be a daunting task. Spreadsheets can quickly become unwieldy and prone to errors, leading to costly mistakes and delays. Fortunately, there's a wide range of BOM software solutions available to help streamline the process and improve accuracy. From simple cloud-based tools to enterprise-level systems, there's a solution for every budget and need.

BOM software offers a variety of benefits, including centralized data management, version control, automated calculations, and integration with other business systems such as ERP and MRP. This integration allows for seamless data flow between departments, ensuring that everyone is working with the same information. No more conflicting spreadsheets or outdated data!

With BOM software, you can easily create and maintain BOMs, track changes, generate reports, and collaborate with colleagues. These tools often provide features like drag-and-drop functionality, visual BOM diagrams, and automated validation rules, making it easier to manage even the most complex BOMs. They help you to be more efficient and more accurate.

Choosing the right BOM software depends on your specific needs and requirements. Consider factors such as the size and complexity of your products, the number of users who will need access to the system, and your budget. Don't be afraid to try out a few different options before making a decision. Many vendors offer free trials or demos, so you can see how the software works and whether it's a good fit for your business. Investing in the right BOM software is an investment in your business's future.

Common BOM Mistakes (and How to Avoid Them)

5. Staying on the Right Track

Even with the best intentions and the most sophisticated software, mistakes can still happen when creating and managing BOMs. The key is to be aware of the common pitfalls and take steps to avoid them.

One of the most common mistakes is inaccurate data. This could include incorrect part numbers, wrong quantities, or outdated pricing information. To avoid this, it's crucial to implement robust data validation processes and ensure that all data is regularly reviewed and updated. Make data accuracy a top priority!

Another common mistake is a lack of version control. Without proper version control, it's easy for different departments to be working with different versions of the BOM, leading to confusion and errors. To prevent this, use a BOM software system that automatically tracks changes and maintains a history of all versions. Version control is your friend.

Poor communication can also lead to BOM errors. If different departments aren't communicating effectively, it's easy for changes to be made without everyone being informed. To avoid this, establish clear communication channels and ensure that all stakeholders are involved in the BOM creation and maintenance process. Communication, communication, communication!

Finally, neglecting to regularly review and update the BOM is a common mistake. As products evolve and processes change, it's important to review the BOM regularly to ensure that it remains accurate and up-to-date. Set a schedule for regular BOM reviews and stick to it. A little maintenance goes a long way.

What Is Sop In Logistics At Shannon Mcelroy Blog

FAQ

6. Demystifying the BOM

Still have questions about BOMs? You're not alone! Here are some of the most frequently asked questions.

7. What's the difference between a BOM and a parts list?

While both list components, a BOM is more comprehensive. A parts list might just show what's needed, whereas a BOM specifies quantities, materials, and even the specific vendors.

8. Is a BOM only for manufacturing?

While primarily used in manufacturing, BOMs can also be beneficial in other areas, such as maintenance and repair. Knowing the exact components of a system makes repairs much easier and more efficient.

9. How often should I update my BOM?

Ideally, you should update your BOM whenever there's a change to the product design, manufacturing process, or sourcing. Regular reviews, at least quarterly, are a good practice.