Out Of This World Tips About How Many Layers Is Arduino PCB

What Are The Layers Of A PCB (Printed Circuit Board)? Viasion

Delving into Arduino PCBs

1. Unraveling the PCB Mystery

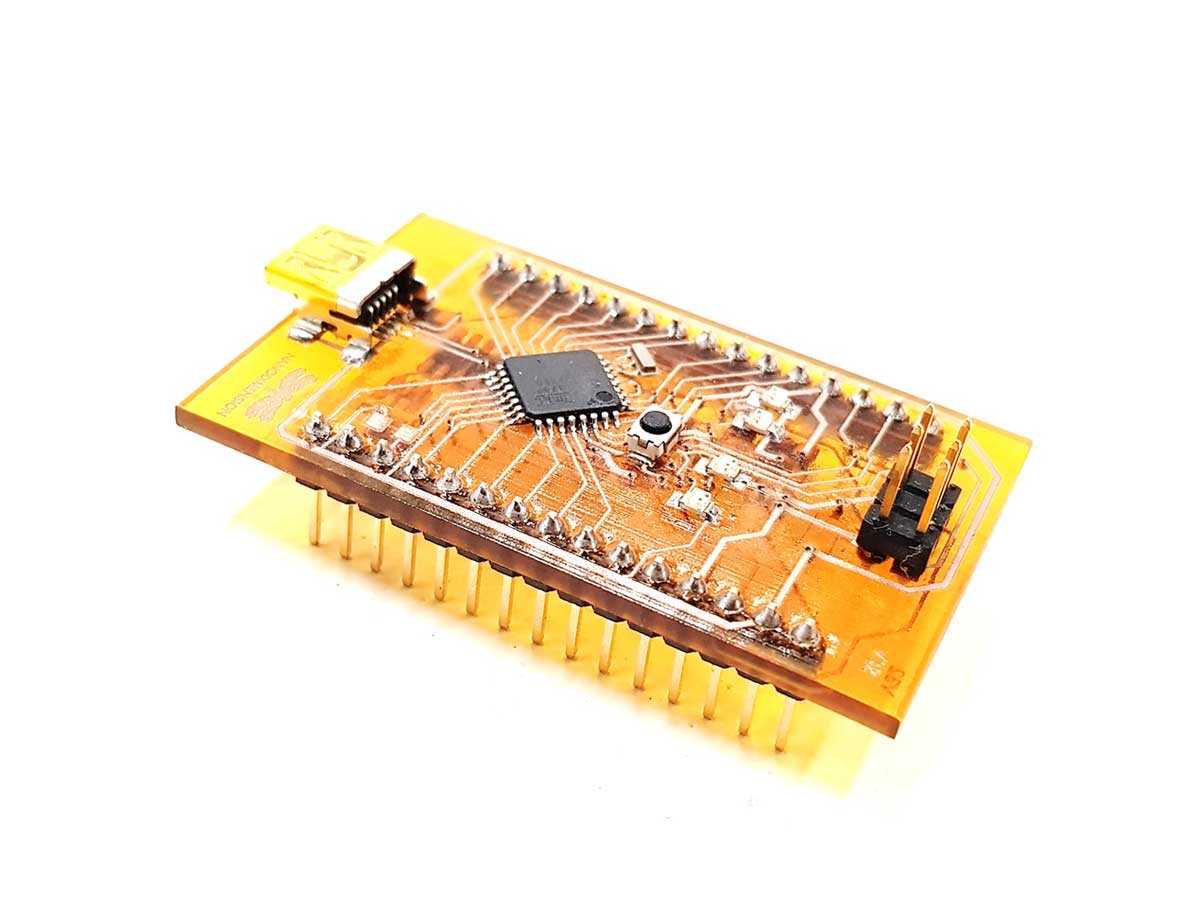

Ever wondered what's beneath the surface of your trusty Arduino board? Beyond the blinking LEDs and user-friendly interface lies a printed circuit board, or PCB, that's the unsung hero of the entire operation. And a key characteristic of that PCB is its layer count. So, how many layers is Arduino PCB typically made of? That's what we're here to explore! You might be surprised at the simplicity and elegance of the design.

In short, most standard Arduino boards, like the Uno, Nano, and Mega, use a two-layer PCB. Yep, just two! This design choice contributes to their affordability and ease of manufacturing, making them perfect for hobbyists and beginners. Think of it as a sandwich two slices of bread (the copper layers) with some essential filling (the insulating material in between).

However, like any good rule, there are exceptions! Some specialized Arduino boards or shields might utilize more than two layers to accommodate complex circuitry or specific performance requirements. It all depends on the features they're trying to pack in. But for the vast majority of your Arduino adventures, you'll be dealing with a trusty two-layer PCB.

Understanding this simple fact can be surprisingly helpful. It gives you a basic grasp of the board's complexity (or lack thereof!) and can inform your decisions if you ever decide to modify or repair your Arduino yourself. Plus, it's just plain interesting to know what makes your favorite microcontroller tick!

The Significance of PCB Layers

2. Why Layers Matter

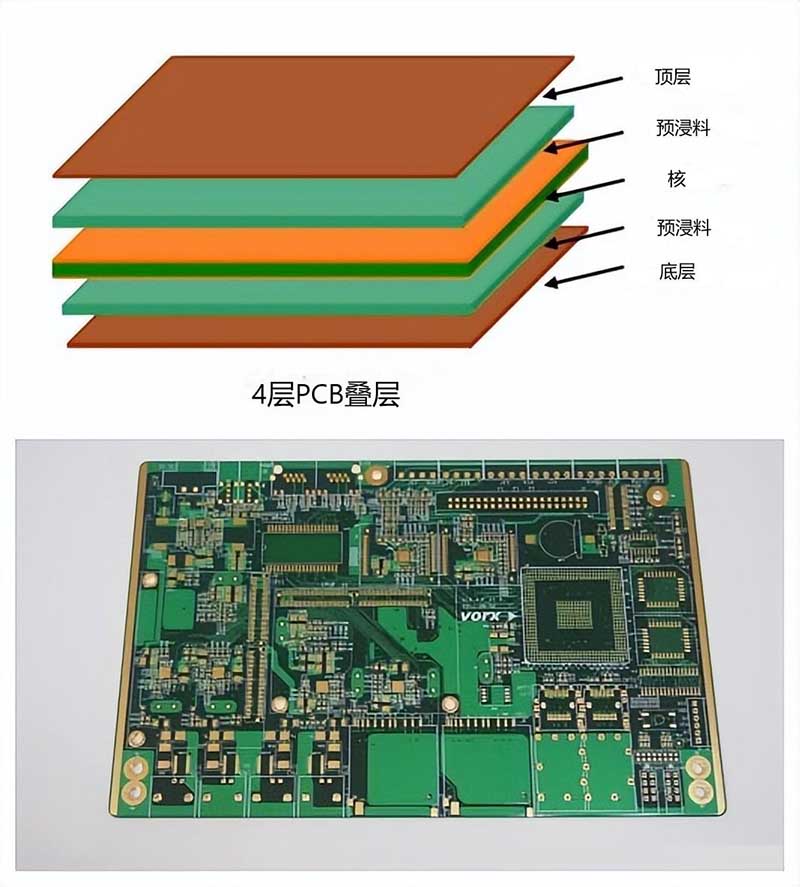

Okay, so most Arduinos have two-layer PCBs. Big deal, right? Actually, it is a big deal! The number of layers in a PCB directly impacts its functionality, complexity, and cost. More layers mean more intricate routing possibilities, allowing designers to cram more components and features onto a smaller board. This is essential for high-density electronics like smartphones and computers, where space is a premium.

With just two layers, Arduino designers need to be creative with how they route the electrical connections. This often involves using both sides of the board effectively, utilizing techniques like vias (small plated holes that connect different layers) to jump between the top and bottom. It's like a carefully planned maze, ensuring that all the signals reach their intended destinations without interfering with each other.

The simplicity of the two-layer design also contributes to the Arduino's robustness. Fewer layers mean fewer potential points of failure, making the board more reliable and durable. This is particularly important for beginners who might be prone to accidental short circuits or other mishaps. Think of it as a simple, sturdy tool that can withstand some abuse.

Ultimately, the two-layer PCB design is a key part of the Arduino's philosophy: accessible technology for everyone. By keeping the hardware relatively simple, the Arduino team made it easier for beginners to get started with electronics and programming without being overwhelmed by complex hardware details.

Exploring Beyond Two Layers

3. The Exceptions to the Rule

While the classic Arduino boards stick to the two-layer approach, the world of Arduino-compatible devices is vast and varied. Some specialized shields, designed to add extra functionality to your Arduino, might employ more complex PCBs. Think of shields that add advanced communication protocols, high-precision sensors, or powerful motor drivers. These often require more layers to accommodate the increased complexity of the circuitry.

For example, a shield that integrates a complex Wi-Fi module might need four or more layers to handle the radio frequency signals effectively. These extra layers provide dedicated ground planes, which help to reduce noise and interference, ensuring reliable wireless communication. It's like building a Faraday cage around the sensitive components to protect them from external disturbances.

Another example is high-current motor driver shields. These shields often need to handle significant amounts of power, and the extra layers allow for wider copper traces, which can carry more current without overheating. This is crucial for driving powerful motors without damaging the board or creating a fire hazard. It's like upgrading the electrical wiring in your house to handle a high-power appliance.

So, while the core Arduino boards are generally two-layer, keep in mind that the Arduino ecosystem is much broader than that. If you're working with specialized shields or custom-designed Arduino-compatible boards, it's always worth checking the PCB specifications to understand the layer count and its implications. It's all about choosing the right tool for the job!

How to Tell How Many Layers an Arduino PCB Has

4. Detective Work for PCB Layers

Alright, curiosity piqued? Want to know if your specific Arduino board is rocking the classic two-layer setup, or if it's secretly a multi-layered marvel? There are a few ways to investigate, though some methods are easier (and less destructive!) than others. Keep in mind that disassembling your board could void any warranties you might have. Im not responsible if you go poking around! Consider this your official "proceed with caution" warning!

First, the most straightforward approach: check the manufacturer's documentation. Arduino usually provides detailed specifications for their boards, including the PCB layer count. A quick search on the official Arduino website or a glance at the board's datasheet should give you the answer. This is always the best starting point.

Second, if the documentation is elusive, you can try a visual inspection. Carefully examine the edges of the PCB. Sometimes, you can faintly see the different layers as thin lines along the cut edge. This is easier if the board has a slightly thicker PCB or if the layers are distinctly colored. However, this method can be tricky, as the layers are often tightly bonded together.

Finally, a more advanced (and potentially destructive) method involves cross-sectioning the PCB. This involves carefully cutting a small section of the board and examining the cut edge under a microscope. This will clearly reveal the number of layers and their arrangement. However, this is obviously not recommended unless you're prepared to sacrifice the board and have access to specialized equipment. Lets face it, just search online!

Types Of Arduino Boards Discover For Best

The Future of Arduino PCBs

5. Peering into the Crystal Ball

So, where do Arduino PCBs go from here? Will we see a shift towards more complex, multi-layered designs, or will the Arduino remain true to its simple, two-layer roots? That's a tough question to answer, but we can make some educated guesses. Given the Arduino's core philosophy of accessibility and affordability, it's likely that the basic Arduino boards will continue to utilize two-layer PCBs for the foreseeable future. This keeps the cost down and ensures that the boards remain easy to manufacture and use.

However, as the Arduino ecosystem continues to evolve, we can expect to see more specialized boards and shields that push the boundaries of what's possible with Arduino. These boards might incorporate more advanced features, such as high-speed processors, complex sensors, or wireless communication modules, and these features might necessitate the use of multi-layered PCBs.

Another factor that could influence the future of Arduino PCBs is the increasing demand for smaller and more compact devices. As technology shrinks, designers are forced to pack more functionality into smaller spaces, and this often requires the use of multi-layered PCBs with finer traces and smaller components. We might see smaller, more powerful Arduino boards that utilize advanced PCB technologies to achieve a higher level of integration.

Ultimately, the future of Arduino PCBs will depend on a variety of factors, including the needs of the Arduino community, the availability of new technologies, and the ongoing pursuit of affordability and accessibility. But one thing is certain: the Arduino platform will continue to evolve and adapt to meet the challenges of the ever-changing world of electronics.

Designing Arduino Nano Hardware Documentation

FAQ

6. Answers to Your Burning Questions

Still have questions about Arduino PCB layers? Fear not! We've compiled a list of frequently asked questions to help you dive even deeper into this fascinating topic.

Q: Are all Arduino boards two-layer PCBs?A: No, while most common Arduino boards like the Uno, Nano, and Mega utilize two-layer PCBs, some specialized boards and shields may have more layers to accommodate complex circuitry.

Q: Why do most Arduino boards use two-layer PCBs?A: Two-layer PCBs are more affordable and easier to manufacture, making them ideal for the Arduino's focus on accessibility and affordability. This design also keeps the boards relatively simple and robust.

Q: How does the number of PCB layers affect the performance of an Arduino board?A: The number of layers impacts routing complexity, signal integrity, and power distribution. More layers allow for more intricate designs and can improve performance in certain applications, but also increase cost and complexity.

Q: Can I modify the PCB of my Arduino board?A: Modifying the PCB is generally not recommended unless you have experience with electronics and PCB design. It can be difficult and risky, and may void any warranties. Always proceed with caution!

Q: Where can I find the PCB specifications for my Arduino board?A: The PCB specifications, including the layer count, are usually available on the official Arduino website or in the board's datasheet. A quick search should point you in the right direction.