Best Info About Are LEDs PWM

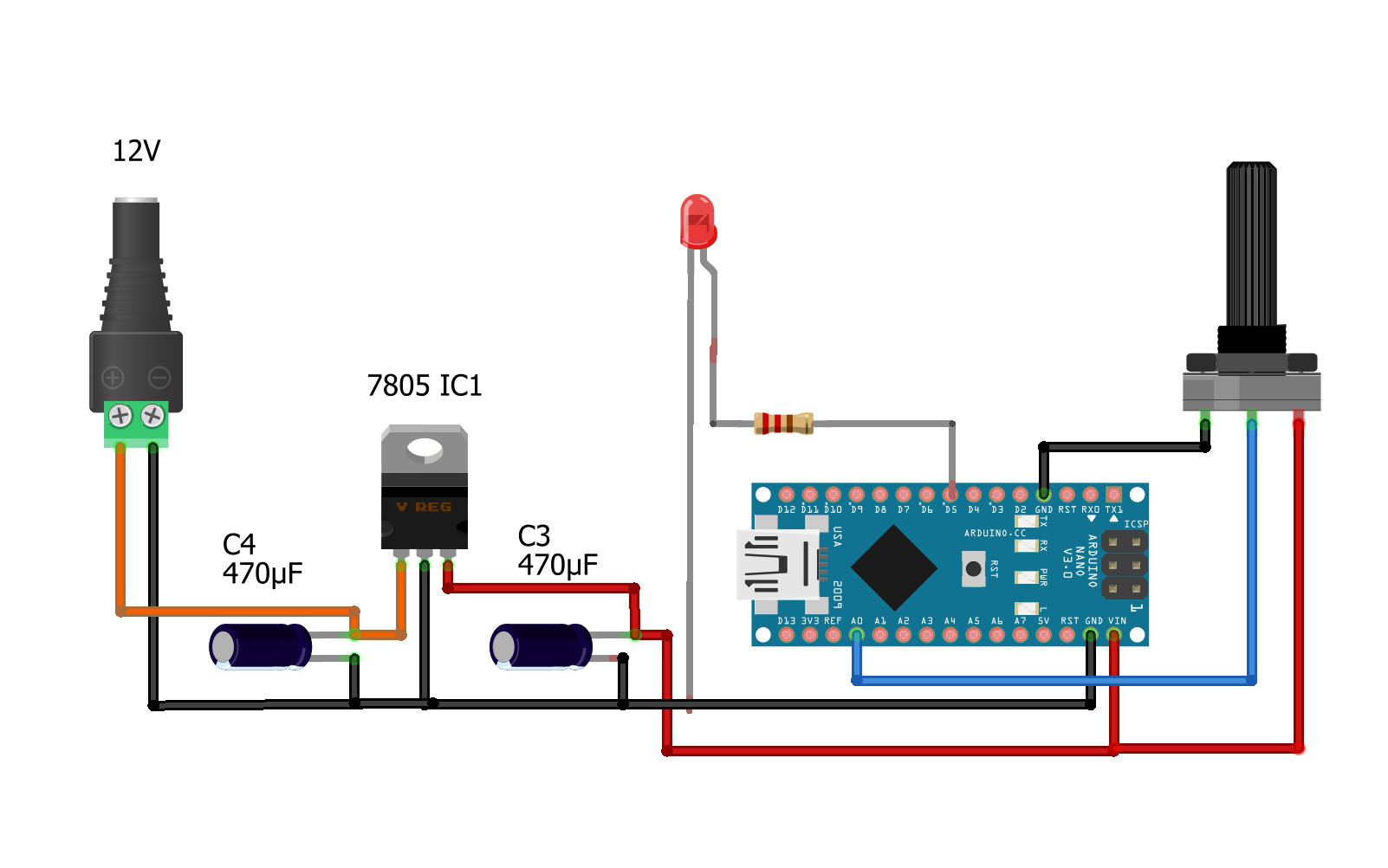

LED Dimmer PWM Controller ESP Web Server ESP32 With Arduino IDE

Are LEDs PWM Controlled? Let's Shed Some Light on the Subject

1. What Exactly Is PWM Anyway?

So, you're wondering about LEDs and PWM. Good question! PWM, or Pulse Width Modulation, is a fancy term for a clever technique used to control the brightness of LEDs. Think of it like a dimmer switch, but instead of mechanically reducing the voltage, it rapidly turns the LED on and off. The duration of the "on" time compared to the "off" time determines the perceived brightness. It's kind of like blinking your eyes really fast — if you blink mostly open, you see more light than if you blink mostly closed. Get it?

Why use PWM? Well, it's efficient! Instead of wasting energy as heat (like a traditional dimmer), PWM simply switches the power on and off. This makes it a great choice for battery-powered devices where every milliamp counts. Plus, it gives you a very precise control over the LED's brightness, allowing for smooth dimming effects and color mixing in RGB LEDs.

The key to making PWM work is speed. The on/off switching happens so quickly that your eye can't perceive the flickering. It just sees a constant level of brightness. The faster the switching frequency, the less likely you are to notice any flicker. We're talking hundreds or even thousands of times per second!

So, is every LED PWM controlled? Not necessarily. Simple LEDs that are just turned on and off don't use PWM. But for any application where you need to adjust the brightness, color, or even communicate data using light (like in some infrared remote controls), PWM is your best friend. It's the unsung hero of the lighting world!

The Role of PWM in LED Applications

2. PWM's Impact on LED Performance and Usability

Now that we know what PWM is, let's see where it's really shining (pun intended!). LEDs are popping up everywhere, from your phone screen to streetlights, and PWM plays a crucial role in many of these applications. Consider your smartphone: the screen brightness is almost certainly controlled using PWM. This allows the phone to dim the display to save battery life or adjust to different lighting conditions.

In architectural lighting, PWM allows for sophisticated dimming and color mixing effects. Imagine a building facade that slowly changes color throughout the night. That's PWM at work! It's also used in stage lighting for creating dynamic and dramatic effects. The ability to precisely control the brightness and color of LEDs opens up a world of creative possibilities.

Even in automotive applications, PWM is prevalent. The brightness of the dashboard lights, the intensity of the brake lights, and even the headlights themselves might be controlled using PWM. This allows for consistent and reliable performance across a wide range of operating conditions.

However, it's not all sunshine and rainbows. Some people are sensitive to the flicker caused by low-frequency PWM, which can lead to headaches or eye strain. This is why it's important to use high-frequency PWM, especially in applications where people are exposed to the light for extended periods of time. Manufacturers are increasingly aware of this issue and are taking steps to mitigate it.

PWM 101 From Duty Cycle To Motor Control

Potential Problems and Mitigation Strategies

3. Addressing Flicker Concerns and Optimizing PWM Settings

As mentioned, the biggest potential drawback of PWM is flicker. While most people don't notice it, some individuals are sensitive to even high-frequency flicker. This can manifest as headaches, eye strain, or even nausea. The key is to use a PWM frequency that is high enough to be imperceptible, ideally above 200 Hz, and even higher for sensitive individuals. The higher, the better, really. It can also depend on the intensity of the LED itself.

Another factor that can affect flicker perception is the duty cycle of the PWM signal. The duty cycle is the percentage of time that the LED is "on" during each cycle. A lower duty cycle (i.e., a dimmer setting) can sometimes make the flicker more noticeable. This is because the "off" time is longer, giving your eye more time to detect the changes in brightness.

Manufacturers can mitigate flicker by using higher PWM frequencies, more sophisticated dimming algorithms, or by adding smoothing capacitors to the LED circuit. Smoothing capacitors act like tiny batteries, storing energy and releasing it during the "off" time, which helps to reduce the perceived flicker.

If you're concerned about flicker from your LEDs, there are a few things you can do. First, check the specifications of the LED or the device it's used in to see what the PWM frequency is. Second, try adjusting the brightness setting — sometimes a slightly brighter setting can reduce the perceived flicker. And finally, if you're really sensitive to flicker, you might consider using LEDs that are dimmed using a different method, such as analog dimming.

How PWM Works.

Distinguishing PWM Dimming from Other Methods

4. A Comparison of Different LED Control Techniques

PWM isn't the only way to dim an LED. Analog dimming, also known as current control dimming, is another method that involves adjusting the current flowing through the LED. This directly affects the brightness of the LED. Unlike PWM, which rapidly switches the LED on and off, analog dimming provides a continuous, smooth change in brightness.

So, which is better? It depends on the application. PWM is generally more efficient, especially at low brightness levels. This is because it's either fully on or fully off, minimizing power losses. Analog dimming, on the other hand, can be more linear and provide a smoother dimming curve. It also eliminates the risk of flicker, making it a good choice for sensitive individuals.

Another important difference is color consistency. With PWM, the color of the LED remains relatively constant regardless of the brightness level. With analog dimming, the color can shift slightly as the current changes. This is because the efficiency of the LED's different color phosphors can vary with current.

In practice, many LED systems use a combination of both PWM and analog dimming. For example, a system might use PWM to coarsely adjust the brightness and then use analog dimming to fine-tune it. This allows for the best of both worlds: high efficiency and smooth dimming with consistent color.

The Analog Side Of PWM LEDs Circuit Cellar

The Future of LEDs and PWM

5. Emerging Trends and Innovations in LED Control

The world of LEDs is constantly evolving, and so is the technology used to control them. One emerging trend is the use of more sophisticated PWM techniques, such as adaptive PWM, which adjusts the PWM frequency based on the brightness level. This can help to further reduce flicker and improve efficiency.

Another area of innovation is the development of smart LEDs that incorporate their own control circuitry. These LEDs can communicate with each other and with a central controller, allowing for complex lighting effects and automated control. They also make it easier to implement advanced dimming and color mixing algorithms.

The rise of the Internet of Things (IoT) is also driving innovation in LED control. Smart lighting systems that can be controlled remotely via a smartphone or a voice assistant are becoming increasingly common. These systems often use PWM to control the brightness and color of the LEDs.

And finally, as our understanding of the potential health effects of flicker grows, manufacturers are becoming more proactive in addressing the issue. Expect to see even higher PWM frequencies and more sophisticated dimming techniques in the future, all aimed at creating a more comfortable and healthy lighting environment. The future looks bright for LEDs, literally and figuratively!

How To Control Led Brightness Using Arduino At Dorothy Bufkin Blog

Frequently Asked Questions (FAQs)

6. Quick Answers to Common Questions

Q: What PWM frequency is considered "safe" for most people?

A: Generally, frequencies above 200 Hz are considered safe for most people. However, some individuals may be more sensitive and require even higher frequencies. Some manufacturers now use PWM frequencies in the kilohertz range to completely eliminate perceptible flicker.

Q: Can I tell if my LED is using PWM just by looking at it?

A: It's difficult to tell with the naked eye, especially if the PWM frequency is high. However, you can sometimes detect flicker by waving your hand quickly in front of the LED. If you see distinct streaks, it's likely using PWM at a lower frequency. Another method is to use a smartphone camera in slow-motion mode; this can reveal the flickering that's otherwise invisible.

Q: Does PWM affect the lifespan of an LED?

A: In most cases, PWM does not significantly affect the lifespan of an LED. LEDs are designed to be switched on and off rapidly, and the switching frequency used in PWM is typically well within their operating limits. However, extremely high PWM frequencies or poorly designed PWM circuits can potentially reduce lifespan, but this is rare.

Q: I get headaches from LED lighting. Could PWM be the cause?

A: It's possible. If you're sensitive to flicker, low-frequency PWM can cause headaches, eye strain, and other symptoms. Try switching to LEDs that are advertised as "flicker-free" or that use analog dimming. You can also try adjusting the brightness of your existing LEDs or using a light meter to check for flicker.